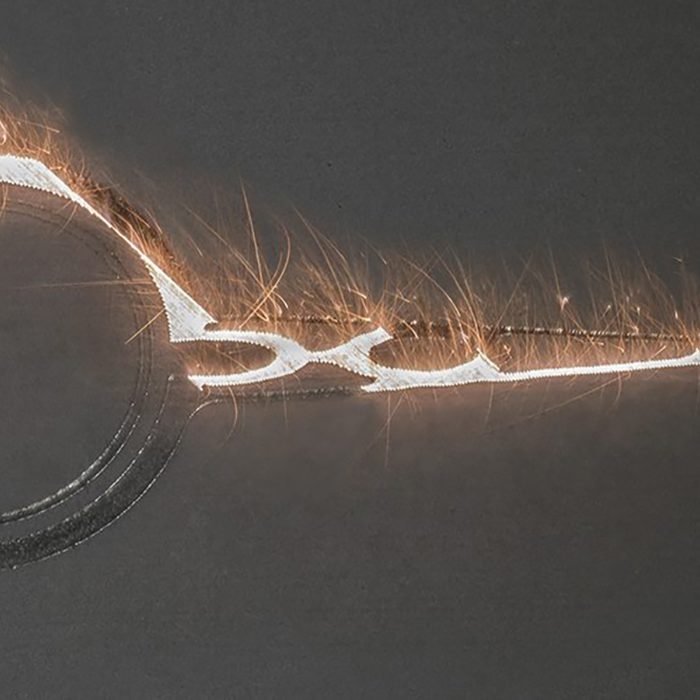

Powder-bed based laser melting is an additive manufacturing process, which allows building complex metal components directly from a 3D file. First, the 3D file is elaborated, adding, if necessary, supports or bases. The three-dimensional model is then sliced into very thin sections (slicing) thanks to a precision software. The file is then sent to the Laser Melting machine, which recognizes each section and recreates the original 3D shape, by melting, layer after layer, the schematized areas. This process can be used to produce components made from multiple metal alloys.

The advantages of additive manufacturing technologies are many: the design phase is free from geometrical limitations (e.g. very complex shapes with internal cavities); the components can be customized and their weight reduced through geometry optimization (lightweighting); assembly phases can be reduced; waste material can be minimized and machining can be limited only to the areas that need tight tolerances and high surface finishing.

Machines

Ciesse was one of the first Italian companies to adopt additive technologies. Active since 2007, Ciesse additive manufacturing department now counts 4 M2 cusing and 1 M1 cusing (Concept Laser, a GE Additive company).Ciesse was the first Italian company to install an X line 2000 R (Concept Laser, a GE Additive company), the world’s largest metal laser melting machine.

XLine 2000R ®

With a build volume of 160 liters – 800 x 400 x 500 mm (x,y,z) – the X Line 2000R is the world’s largest metal laser melting machine for the toolless manufacture of large functional parts. The X Line 2000R is used for producing large-scale components in the aerospace and automotive industries. Our X Line 2000R is specialized in the processing of Nichel-based alloys (Inconel 718, Inconel 625).

More technical information about the machine is available at this link.

M2 Laser Cusing

With a build volume of Max. 245 x 245 x 350 mm (x,y,z), the M2 Series 5 – now available with dual 1kW lasers – is the last M2 model installed in Ciesse. The additive manufacturing department of the company now counts also 3 M2, previous model. The M2 Series 5 was optimized in terms of speed and productivity, reliability, uptime and quality control.

More technical information about this machine is available at this link.

M1 Laser Cusing

With a build volume of 250X250X250 mm, the M1 Cusing is designed to work with materials such as steel.

Materials

STEEL BASED ALLOYS

M300

AISI 630 (17-4 PH)

AISI 316L

ALLOYS FOR THE BIOMEDICAL SECTOR

CoCrW

Ti6Al4V-ELI (ASTM F-136)

NICHEL BASED ALLOYS

Inconel 625

Inconel 718

TITANIUM BASED ALLOYS

Ti6Al4V

ALUMINUM BASED ALLOYS

AlSi12

AlSi7

Main Fields of Application

Racing e Automotive

Since the Nineties, Ciesse has been supplying components for Formula 1™ and more specifically for Ferrari Gestione Sportiva. If you want to discover more about the products manufactured for the racing sector follow the link.

Molds

The company manufactures molds with conformal cooling using the powder-bed metal fusion technology. The ability to build internal channels is one of the competitive advantages of additive

manufacturing.

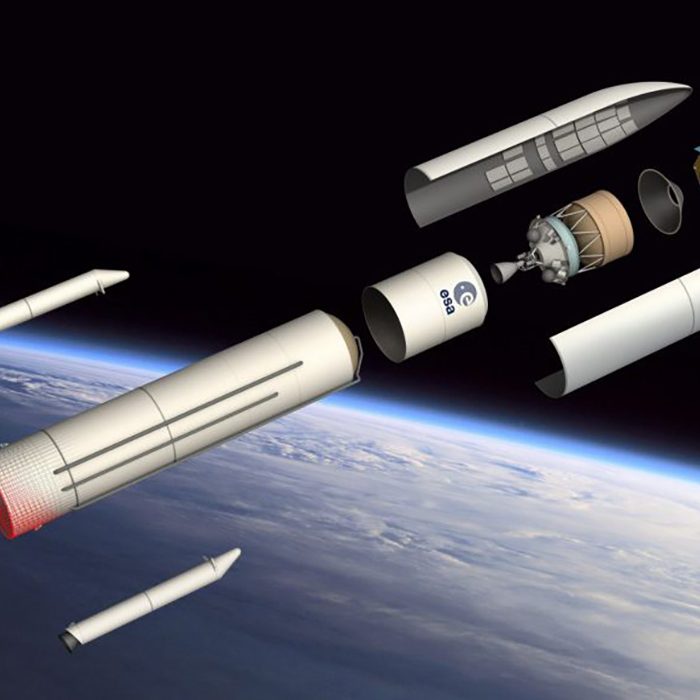

Aerospace and Defence

For the aerospace and defense sectors, Ciesse produces prototypes and small series, mostly with

additive technologies, with the creation of complex geometries that allow for the optimization of the

performance.

Aviation

Ciesse has been working for the commercial aviation sector for several years now with serial

productions manufactured both completely through machining and through secondary machining operations on components manufactured through Metal Injection Molding.

Ciesse at RM Forum 2021, the conference dedicated to the Italian additive manufacturing ecosystem

Ciesse celebrates 13 years of additive manufacturing

Our Services

Additive Manufacturing

Powder-bed fusion laser melting is an additive manufacturing process that allows for the

manufacturing of complex metal components directly from a 3D file. First, the 3D file is elaborated

through specialized software and supports necessary for the build process and easy to be

removed in the post-production phase are added.

Machining

The combination of additive manufacturing and machining techniques is one of the most advanced technological mix to produce high-precision mechanical components. Ciesse milling, turning, electro-discharge machining departments allow, one side, to manufacture series of components totally produced through chip removal; on the other side, the same departments allow performing the necessary secondary operations on raw components manufactured by additive manufacturing.

Quality Control

Ciesse testing department has three main objectives: to verify that supplied materials (raw or semi-finished) comply with quality standards; to support departments involved in the production process of mechanical components and to test finished parts, providing all certifications that a given client requires.

3D Modeling

DfAM – Design for Additive Manufacturing (DfAM) is one of the most interesting frontiers, because it allows rethinking the design phase as to optimize all the advantages offered by the powder-bed laser melting (ex. light weighting)