Contact us

Ci-Esse srl. Via Montegrappa, 27

Loc. Ubersetto 41042 FIORANO (MO)

+39 0536843567

info@ci-esse.it

Orders, invoices, shipments:

ramona.medici@ci-esse.it

Request for quotation (RFQ):

info@ci-esse.it

Our Services

Additive Manufacturing

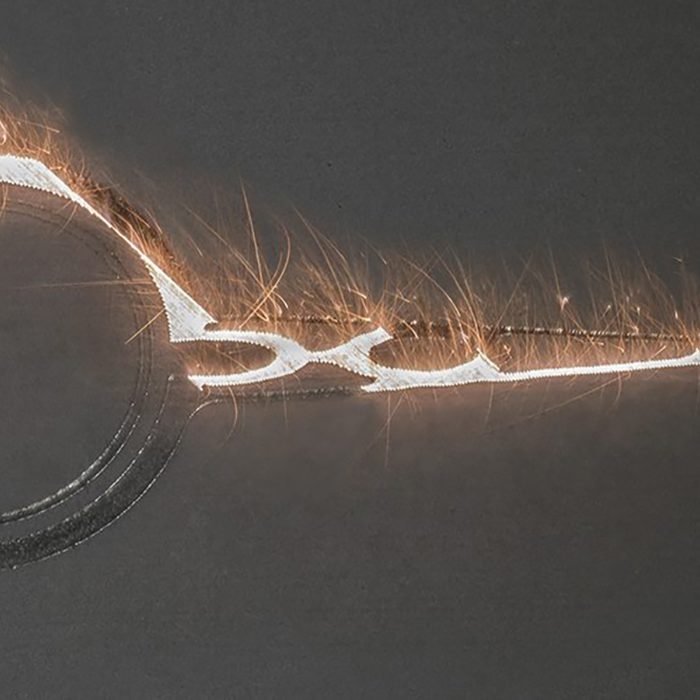

Powder-bed fusion laser melting is an additive manufacturing process that allows for the

manufacturing of complex metal components directly from a 3D file. First, the 3D file is elaborated

through specialized software and supports necessary for the build process and easy to be

removed in the post-production phase are added.

Machining

The combination of additive manufacturing and machining techniques is one of the most advanced technological mix to produce high-precision mechanical components. Ciesse milling, turning, electro-discharge machining departments allow, one side, to manufacture series of components totally produced through chip removal; on the other side, the same departments allow performing the necessary secondary operations on raw components manufactured by additive manufacturing.

Quality Control

Ciesse testing department has three main objectives: to verify that supplied materials (raw or semi-finished) comply with quality standards; to support departments involved in the production process of mechanical components and to test finished parts, providing all certifications that a given client requires.

3D Modeling

DfAM – Design for Additive Manufacturing (DfAM) is one of the most interesting frontiers, because it allows rethinking the design phase as to optimize all the advantages offered by the powder-bed laser melting (ex. light weighting)